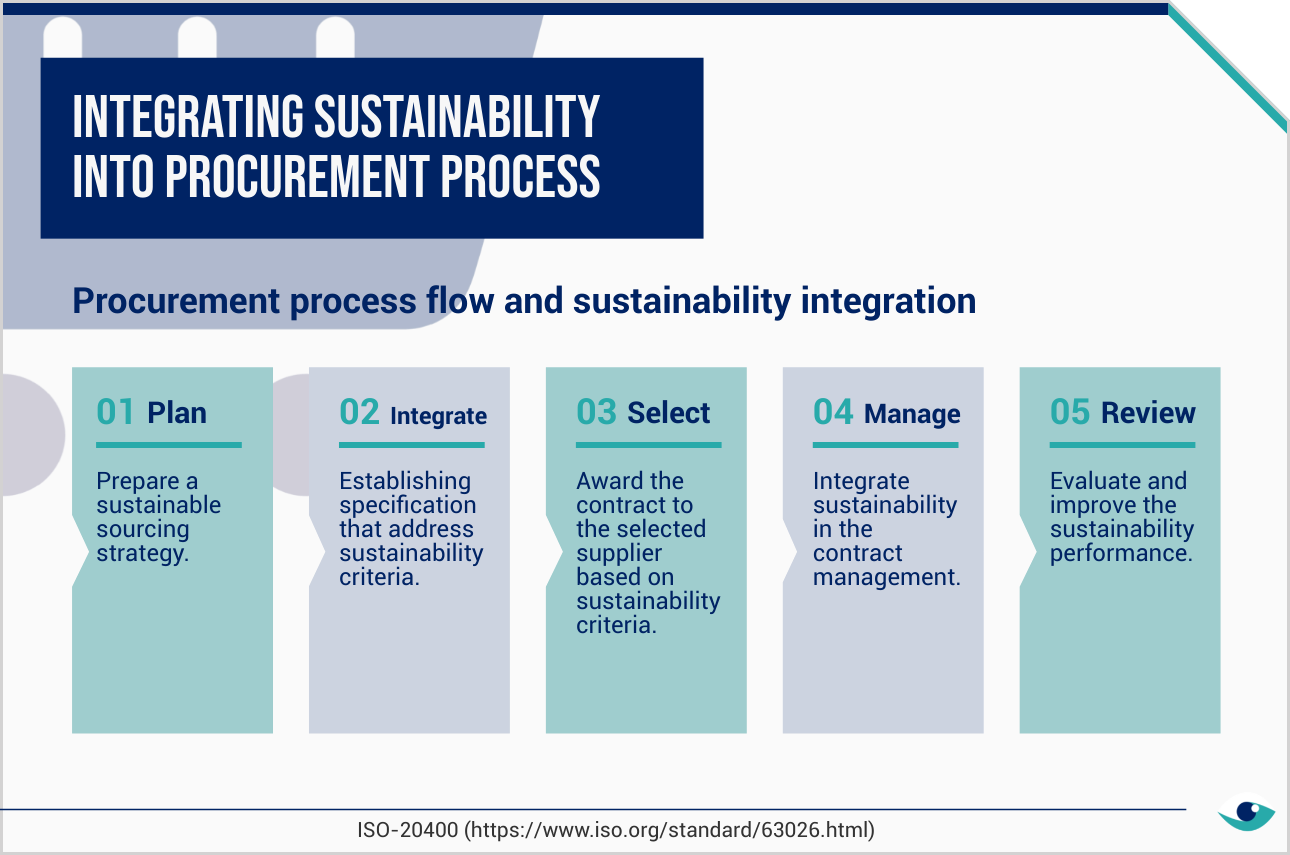

In April 2024, the US Department of Defence, among other government bodies, instructed federal agencies to embrace "sustainable procurement" of products and services. Other leading regulators are also introducing legislative proposals to define and encourage a focus on sustainable sourcing. Within the consumer durables manufacturing industry, this regulatory shift presents challenges and opportunities for industry leaders to implement across the supply chain. Organisations can secure sustainable sourcing by adopting balanced scorecard methodologies that integrate sustainability with service, quality and cost metrics, as recommended by ISO-20400.

Enhancing compliance through sustainable sourcing

Exploring strategic supplier engagement to boost sustainability in procurement and compliance in the consumer durables sector

Value chain: upstream

Consumer durables manufacturing

AT A GLANCE

Sustainable sourcing mitigates risks such as regulatory non-compliance and environmental harm for consumer durables.

Addressing these risks is crucial for maintaining brand reputation and ensuring long-term financial stability.

Long-term, effective sustainability practices in sourcing can lead to industry-wide standards and foster innovation.

Supplier assessments

Organisations should assess suppliers' capacity to contribute to their sustainability expectations through the supply of consumer goods. Failing to implement sustainable sourcing can increase regulatory and environmental risks. The percentage of new suppliers screened using environmental criteria can be disclosed in accordance with GRI 308. Regular assessments can ensure that suppliers meet the organisation’s stringent environmental criteria and sustainability goals.

Supplier engagement

Consumer durables manufacturers should also implement a system that establishes baseline measurements, sustainability goals and metrics for assessing supplier performance. Collaboration with EcoVadis has enhanced Whirlpool Corporation’s ability to conduct due diligence activities. Whirlpool has adopted rigorous supplier assessments to ensure compliance with sustainable procurement standards. There is an opportunity to establish long-term supplier relationships based on aligned sustainability objectives and regulatory requirements.

Monitoring methods

Organisations use methodologies to monitor sustainability alongside service, quality, delivery, cost and technical requirements. Midea is committed to transparent industrial chains, focusing on suppliers from regions with varied environmental and social challenges. The systems used to assess the impacts of terminating a relationship with a supplier are detailed under GRI 308. This comprehensive approach ensures all aspects of supplier performance are evaluated consistently.

Long-term tactics

Performance monitoring is essential to ensure suppliers meet sustainability-related requirements. Havells India has established processes to encourage sustainable practices among suppliers, including environmental audits and others based on ESG criteria. Environmental supplier criteria have grown significantly in consumer durables manufacturing since the practice first emerged in 2020. Successful organisations will be those that can track and disclose social and environmental performance in the supply chain.

FURTHER READING

- Sustainable procurement guidance (ISI 20400 - requires payment)

- Sustainable Procurement Definition (Ecovadis)

- Best practices in procurement (Sustainable Procurement Platform)