As demand for transparency and ethical practices intensifies, the fashion & personal care industry faces growing pressure to manage risks related to raw material sourcing, such as supply chain disruptions and reputational damage, especially in conflict-prone and environmentally sensitive regions. Sourcing raw materials like cotton, leather and precious metals is increasingly challenged by climate change, land use conflicts and resource scarcity, impacting supply chain reliability and costs. Businesses should align with OECD guidelines and adopt Kering Standards to mitigate risks, uphold ethical standards and enhance brand integrity and competitiveness.

Enhancing sourcing practices in fashion & personal care

Promoting transparency and ethical procurement in the supply chain to mitigate risks associated with raw materials sourcing

Value chain: upstream

Fashion & personal care

AT A GLANCE

The fashion & personal care industry faces significant reputational and operational risks related to material sourcing.

This risk is crucial due to increasing climate change impacts and the need for ethical practices.

Addressing these challenges can enhance brand integrity, ensuring future sustainability and competitiveness.

Supplier engagement

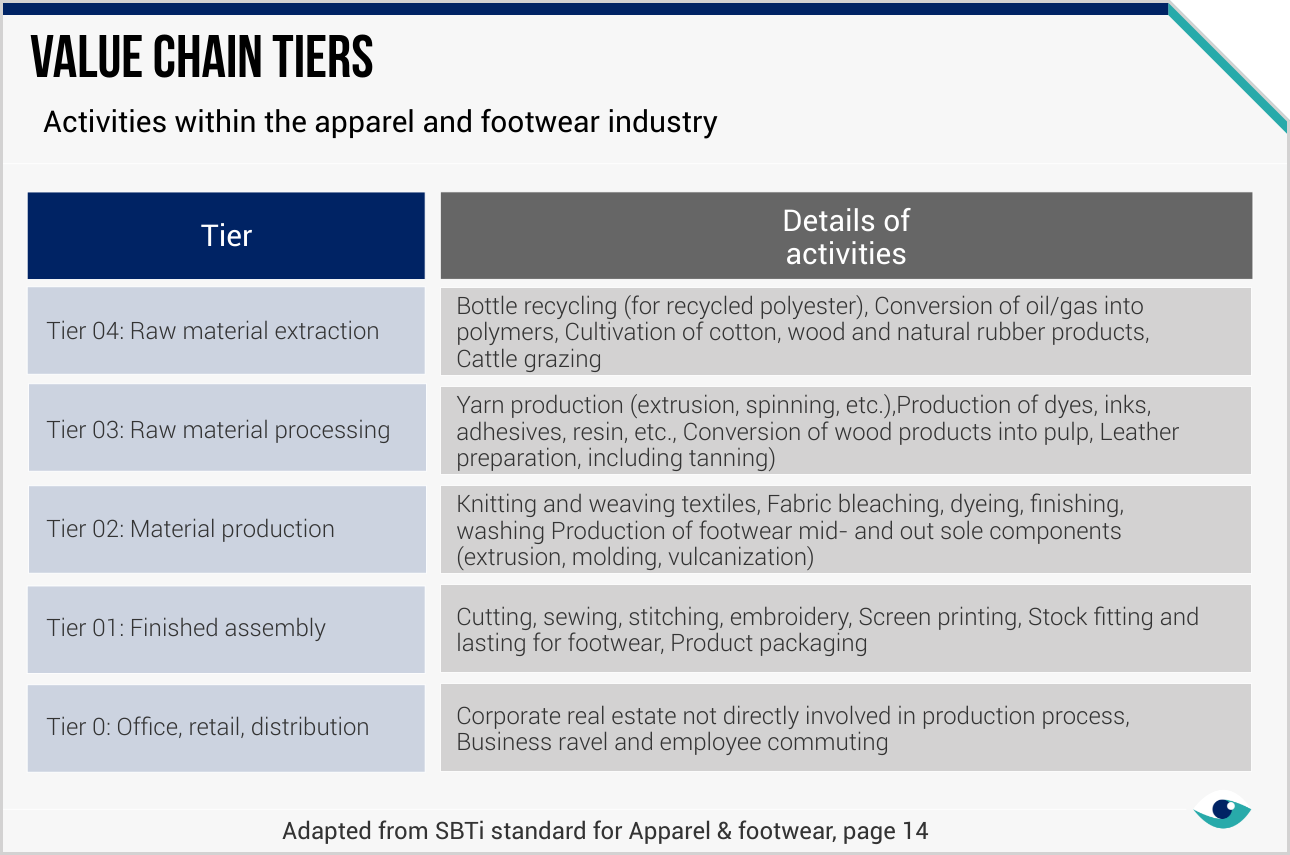

Entities in the fashion & personal care industry that proactively engage with suppliers and use certification standards can more easily mitigate risks such as price volatility and supply disruption, enhancing transparency across the supply chain. The industry's evolution has included a focus on using innovative alternative materials and introducing circular economy practices. Supplier mapping helps enterprises manage environmental and labour risks associated with raw materials like leather.

Transparency rules

Under the SASB's industry standard for apparel, entities are required to disclose a list of priority raw materials and discuss the business risks or opportunities associated with procuring supplies. SASB disclosures include environmental or social factors most likely to threaten sourcing and the amount of each raw material that is certified to a third-party standard. Organisations carrying out supplier assessments should consider forced labour risks in different regional contexts as part of due diligence.

Evaluating high-risk areas

Assessing suppliers in water-stressed areas and high-risk countries is crucial, particularly regarding garments and footwear. High rates of informal employment in cotton harvesting and leather stitching in the global South underline the need for more sustainable employment practices. Organisations should be especially aware of forced labour supply chain risks. Furthermore, effective wastewater management in processes like cotton growing and wet-processing is essential.

Strategic sourcing

Richemont's programme on raw material sourcing emphasises continuous improvement and regulatory compliance. Prada's goal to convert all purchased leather to LWG-certified tanneries by 2024 highlights efforts to align with global standards. Kering’s commitment to the Kering Animal Welfare Standards illustrates a unique approach. In the future, procurement activities in the industry will become more sophisticated. Trade mapping will be applied by more leading organisations to improve traceability and reduce risk.