In August 2024 the UK government awarded GBP 444,739 (USD 563,560) for a project to decarbonise the Midlands aerospace cluster – home to 3% of the aerospace industry – by engaging with aerospace supply-chain firms located there to identify processes and operations that emit greenhouse gases, and using local experts to help assess proposed solutions. State support towards curbing aerospace firms’ upstream emissions, which account for 2–7% of their value-chain emissions, according to Roland Berger, a global consultancy, is vital to the aviation industry’s 2050 net-zero emissions goal. Improving data, supplier engagement and materials usage can help too.

Aerospace companies seek to limit their suppliers’ emissions

Availability of and access to good data, supplier engagement and low-carbon materials can help curb these indirect value-chain emissions

Value chain: upstream

Aerospace

AT A GLANCE

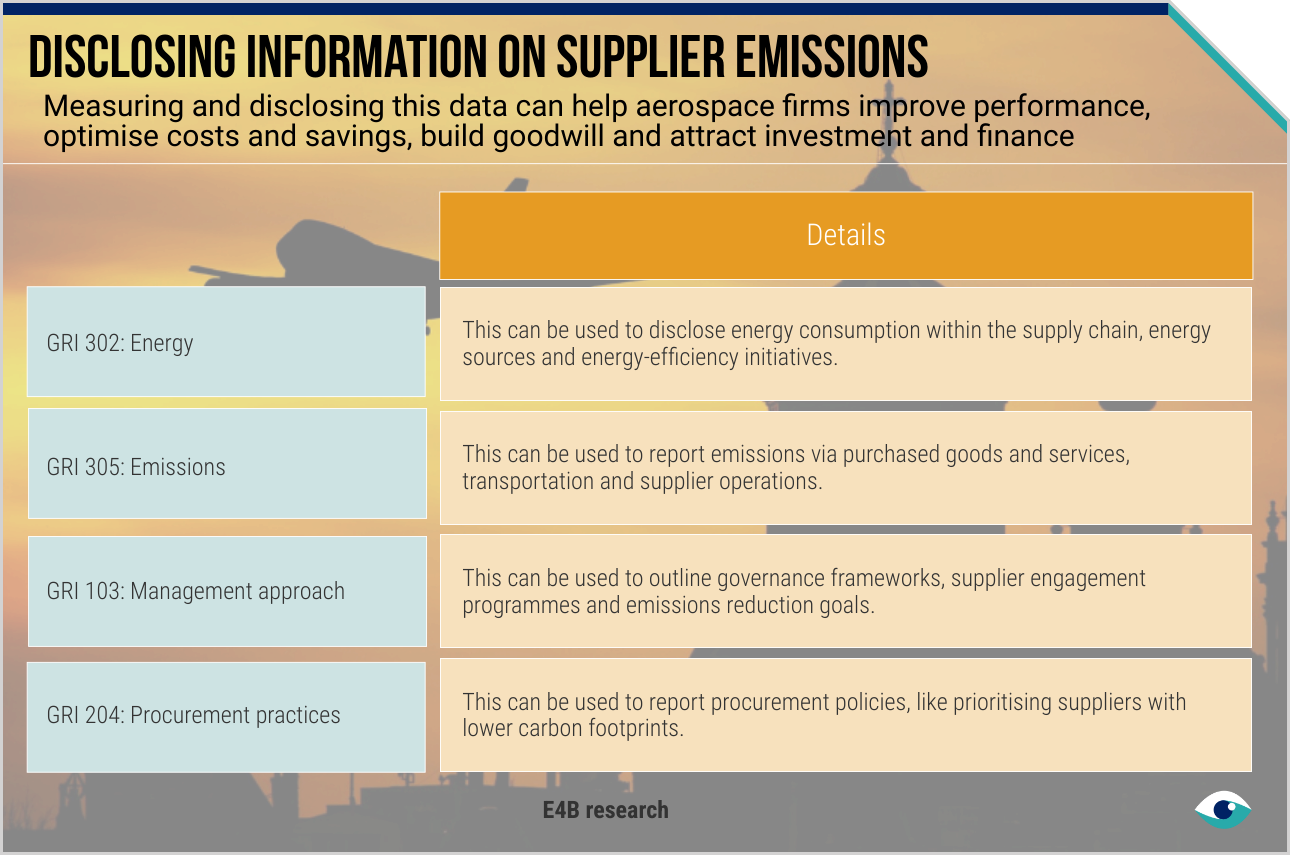

Aerospace companies increasingly seek to measure, disclose and curb their suppliers’ emissions.

To do so, many are improving corresponding data availability, access, quality and analysis, supplier engagement and materials usage.

Growing investor, financier, regulator and public scrutiny will raise pressure on companies to have supplier emissions-reduction plans in place.

Data

Poor data availability, access and quality – often due to non-collection, limited resources, data-sharing rules and competition concerns – limits the assessment of supplier emissions. Airbus SE’s Skywise platform enables suppliers to use in-flight, engineering and operational data to optimise each component’s design, materials, maintenance, and recycling or reuse, to limit production and logistics emissions. Increasing supplier data and using industry averages can aid estimation and target setting.

Supplier engagement

Prioritising suppliers based on their emissions levels and progress towards decarbonisation can help aerospace firms optimise resource allocation and support for suppliers developing and implementing decarbonisation strategies. Safran SA is mobilising its 400 most emissions-intensive suppliers to commit to emissions-reduction plans that are consistent with the Paris Agreement on climate change by 2025, and factors carbon maturity and an internal carbon price into its supplier selection process.

Materials

Aluminium, titanium and composite materials are vital to aerospace components, but their production is energy- and emissions-intensive. Using green aluminium, composites made of low-carbon carbon fibre and bio-based resins, recycled metals and additive manufacturing can curb suppliers’ emissions. RTX Corporation identifies and collects scrap and machining chips from internal manufacturing sites and returns them to raw material makers, who clean and remelt the materials to produce new metal.

Industrywide initiatives

RTX Corporation reports emissions from purchased goods and services, and capital goods via a tool from the International Aerospace Environmental Group (IAEG), which includes Airbus SE, Boeing Company, Bombardier Inc, Embraer SA, Lockheed Martin Corporation, Northrop Grumman Corporation, Rolls-Royce Holdings plc, RTX Corporation, Safran SA and TransDigm Group Inc. IAEG Sustainability Assessments help Airbus SE, Boeing Company, Lockheed Martin Corporation and RTX Corporation evaluate supply chains.

FURTHER READING

- GHG reporting guidance for the aerospace industry (International Aerospace Environmental Group)

- Aviation net-zero CO2 transition (International Air Transport Association)

- Sustainability in the aerospace and defense industry (KPMG)