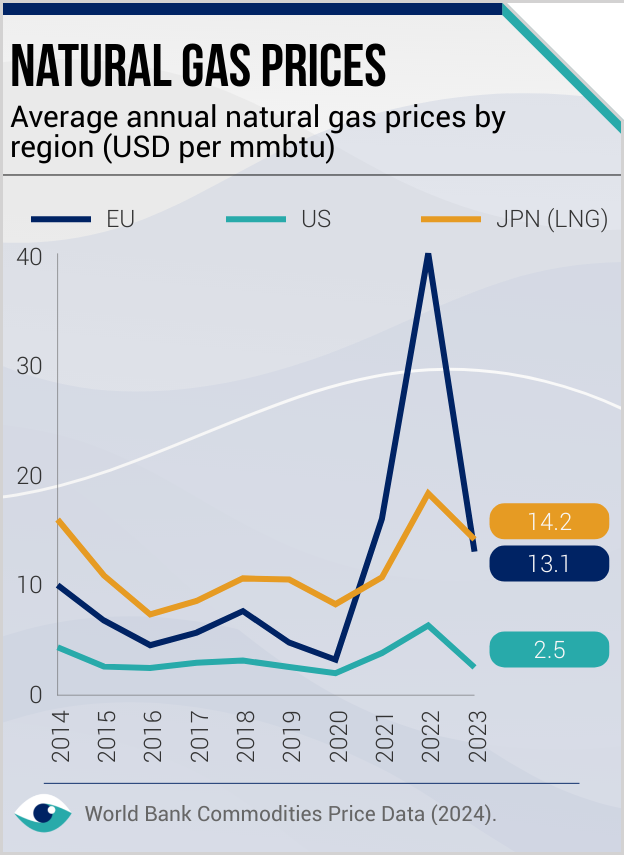

The chemicals industry has been pinched by elevated fossil fuel input costs over an unusually long duration, massive drops in demand impacting profitability and continued pressure to reduce environmental footprints. Chemical industry margins have always been at the mercy of variations in input prices. Drawn-out issues in recent years mean chemical leaders have sought out competitive advantages through circular economy principles as a source of low-cost material inputs. Replacing natural gas through circular means would be of huge value. Other objectives, such as molecule recycling, face challenges at scale, but have still been explored in discrete cases.

Chemical industry circular economy opportunities & challenge

New processes using CO2 and H2 reduce fossil fuel reliance, offering sustainability and cost advantages

Value chain: upstream

Chemicals

AT A GLANCE

Elevated fossil fuel costs and declining demand have pressured the chemicals industry, driving leaders to explore circular economy solutions for low-cost material inputs.

Immediate implications include reduced reliance on natural gas through the Sabatier process.

Long-term, investment and policy support are needed for widespread adoption and industry transformation.

Making use of waste CO2

Where surplus H2 is available, reliance on natural gas can be reduced by combining H2 with CO2 through the Sabatier process. Pure CO2 generated through carbon capture and storage (CCS) or direct air capture (DAC) can be a material input into the Sabatier process to produce synthetic natural gas, reducing reliance on natural gas. A source of hydrogen could be derived at chemical production hubs (where multiple processes are integrated on site) to react with the CO2 to produce CH4 (natural gas).

Circular molecule reality

Up to 60% of molecules in Europe can theoretically be recirculated by the industry at any one time. Realising such levels of recovery and reuse would however require significant change. This would require step changes in upfront investment in new technologies, processes and infrastructures. Companies would need to develop a cross-functional approach and reform internal cultures. Policy would also be needed to support cross-border value chains subject to variations in local regulations.

Circular projects abound

The challenges of a large-scale circular chemical industry do not preclude the development of individual projects and processes deploying circular principles. Air Products has partnered with World Energy on the construction of a USD 2 billion Sustainable Aviation Fuel (SAF) facility in the US. The facility will use H2 and CO2 to manufacture fuel via the Sabatier process. German materials innovator Covestro confirms positive laboratory results for its pilot plant recycling flexible foam.

Despite the challenges

Policymakers must support cross-border value chains and harmonise regulations to enable a circular chemical industry. Air Products and World Energy are pioneering circular principles by building a USD 2 billion SAF facility using H2 and CO2 via the Sabatier process. Widespread adoption will need investments in new technologies, integrated processes, and a shift in internal organisational cultures. This will position the industry as a leader in sustainability and attract environmentally conscious investors.

FURTHER READING

- Sabatier reaction (ScienceDirect)

- Taking the European chemical industry into the circular economy (Accenture)

- Air Products teaming up with World Energy (Air Products)