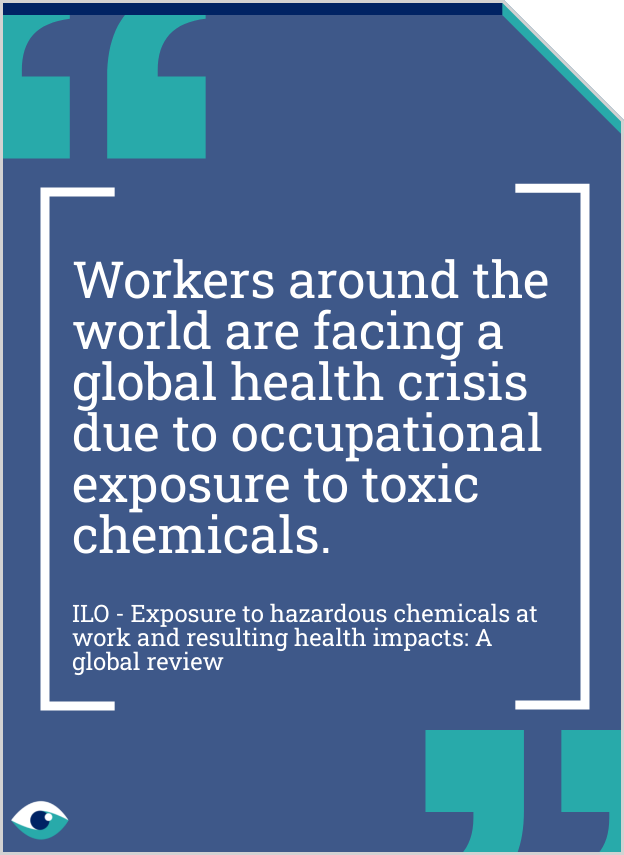

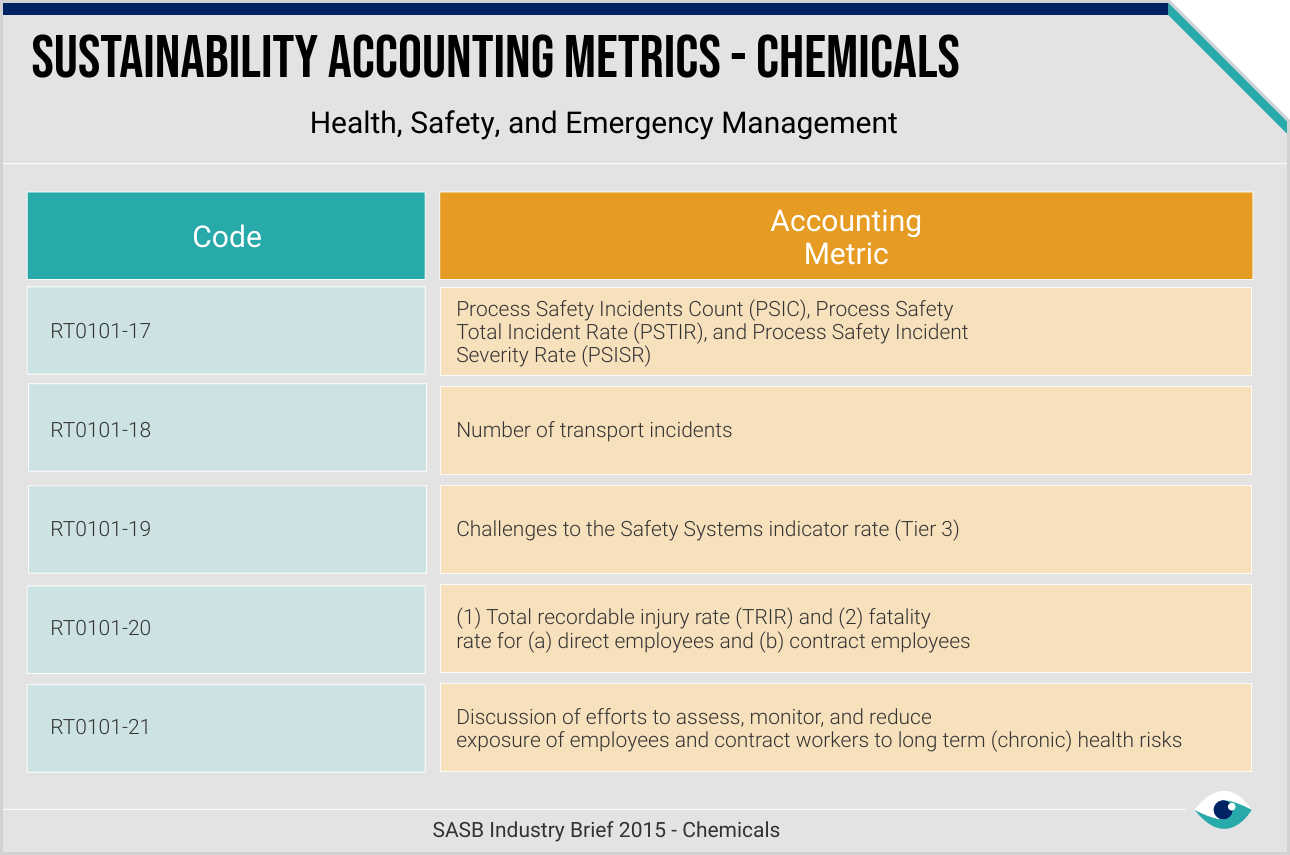

The International Labour Organization (ILO) says a billion workers are exposed to hazardous substances each year and that the expansion of chemical production and industries using them leads to a greater potential for occupational exposure. Hazardous substance exposure can result in death, disability, or chronic disease. Chemical manufacturers risk operational suspension and the imposition of civil and criminal liabilities including penalties and damage awards in consequence. The ILO states any incident where a worker is harmed is “entirely preventable.” Leading manufacturers use SASB frameworks to disclose exposures and efforts to protect employees.

Recognising the risk of hazardous waste management

Whether through direct use, storage, transportation or disposal, leading chemical manufacturing firms embody a heightened risk awareness

People: Social & Governance impacts

Chemicals

AT A GLANCE

Chemical manufacturers are particularly exposed to risks associated with hazardous waste management.

There’s a danger of death or disability for employees, leading to liabilities and impacts on bottom-line performance and investor sentiment for companies.

New chemicals and changing occupational exposure limits add further complexity to a highly regulated industry.

Exposure limits

The ILO says expansion and new chemicals mean that mechanisms to regulate exposure, such as occupational exposure limits (OELs), struggle to keep up, creating an urgent need for action to prevent harm to workers. A 2021 review’s OEL priority action areas recommend developing, updating, and harmonising limits with approaches that include covering all workplace chemicals rather than focusing on individual chemicals or single health effects.

Workplace actions

Highly proactive approaches to protecting workers from exposure to chemical hazards as part of hazardous waste management may require initial investment but mitigate risks of liabilities, penalties, and higher future costs of capital. Local operational actions include the identification of chemicals, determination of risk, and implementation of controls. Provision and maintenance of personal protective equipment (PPE), information and training, and medical and health surveillance are vital.

Active engagement

At-risk employees are better protected when they are actively engaged. SABIC introduced its WE CHOOSE SAFETY initiative in 2022 to do just that using a mobile training trailer and virtual reality simulations. SABIC also holds safety campaigns onsite and online, which include live virtual events. The company investigates in depth the reasons for human failures that result in injury incidents, uses comprehensive internal process and hazard training, and enrolls employees in NEBOSH diplomas.

Inaction not a viable option

The risk of inaction regarding hazardous chemicals is significant for firms in the manufacturing industry. Cases of chemical contamination of soil and groundwater impose investigation costs, and can require financial provisions for future penalties and remediation costs. There are also the attendant risks to reputational capital and potential disruption to business activities. Many leading firms in the chemicals industry recognise distinct risks associated with use, transport and storage of hazardous substances both in their direct operations and supply chain.