Despite rising concern over COCs, tests discover alarmingly high levels of bisphenols, phthalates, and PFAS (per- and poly-fluoroalkyl substances). Consumer Reports recently found high levels of phthalates in many foods, including peaches, yogurt, salmon, and fast foods. PFAS has been found in biodegradable products at levels above EU limits. Growing legislation can be geographically inconsistent, and consumer understanding of COCs is lacking. Packaging companies face a landscape in which they must monitor materials and govern COCs to avoid non-compliance, fines, legal action, and loss of custom and credibility while providing competitive products.

Packaging companies focus on chemicals of concern

Global packaging companies are increasingly transparent in their efforts to reduce and remove chemicals of concern in food packaging

People: Social & Governance impacts

Packaging

AT A GLANCE

Chemicals of concern (COCs) cause substantial health impacts for consumers. However, awareness is low and COC levels are high in many products.

Legislation is developing but inconsistent. Packaging companies must navigate a changing industry and mitigate risks.

Periodic reports provide transparency to stakeholders, demonstrating compliance by testing and new initiatives.

Standards compliance

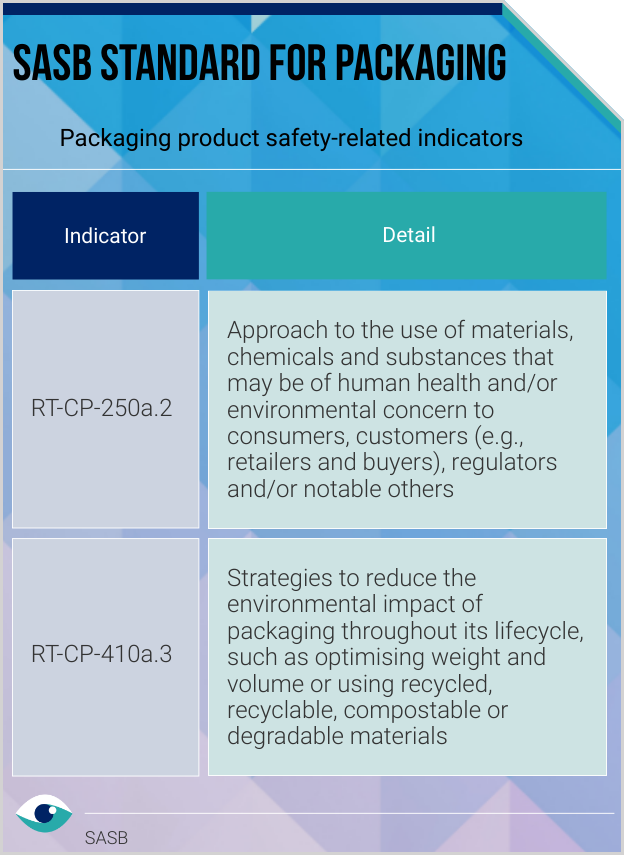

Packaging company annual and sustainability reports reveal actions and standards to stakeholders, including the public, in order to build trust and credibility. Companies such as Amcor, UPM, and Stora Enso are clear about their adherence to EU, local and ISO standards, including the EU’s regulations for chemicals (REACH), Classification, Labelling, and Packaging (CLP) Regulation, ISO 9001, ISO 22000, FSSC 22000, ISO 14001, ISO 50001 and ISO 45001 standards, as well as the FDA’s requirements.

Scrutiny and substitution

Effective governance of materials, processes and suppliers must be clearly demonstrated. Crown Holdings collaborates with suppliers to substitute or eliminate materials of concern or seek third-party safety confirmation. Crown screened its food contact materials, examining 1,000 chemicals based on publicly available materials such as ChemSec’s Substitute-It-Now (SIN) List and its own evaluations. UPM has improved chemical management and screens suppliers based on product safety.

Value chain management

Leading companies closely monitor suppliers to ensure the same levels of compliance throughout the value chain. For example, UPM sourcing organisations follow clearly defined selection criteria. International Paper uses a matrix of raw material requirements that varies by application, jurisdiction, and regulatory standards. Stora Enso requires suppliers to comply with group product safety requirements. Stora Enso tests food contact material from suppliers in line with regulatory requirements.

Innovation for longevity

Industry leaders align food safety and environmental concerns and engage employees in ideation. International Paper Company spends millions on research and development each year and has numerous patents and trademarks. In 2021, its Global Cellulose Fiber team led an event on the circular economy, engaging over 100 employees across every business function. During the event, more than 100 ideas surfaced to replace plastic and petroleum-based materials that are now being tested for feasibility.

FURTHER READING

- Get PFAS out of food packaging materials ASAP (Food engineering)

- In pursuit of clean packaging with no chemicals of concern (Food safety)

- Consumer concern over PFAS ‘forever chemicals’ continues to grow (Civic Science)